Measurement Systems

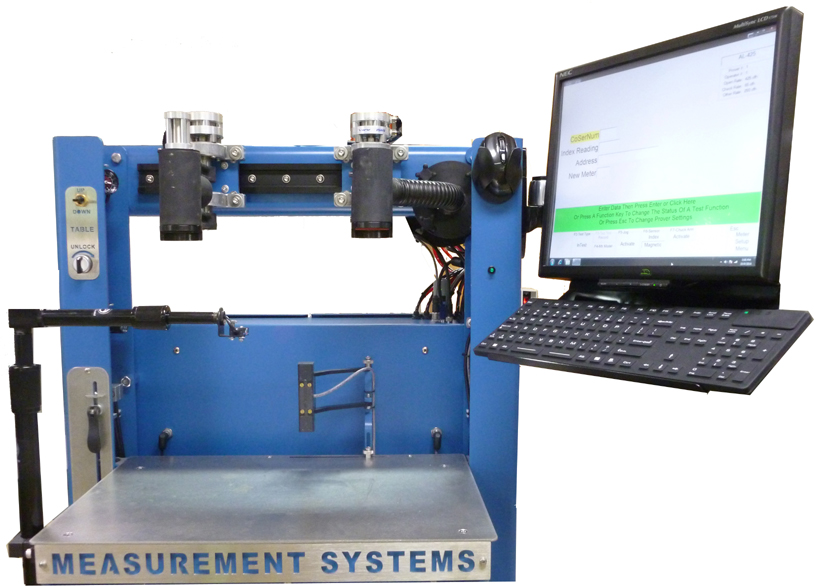

Computer Prover SN-II

Computer Prover SN-II Demonstration

THE RELIABLE AND AFFORDABLE SONIC NOZZLE PROVING SOLUTION

Measurement Systems Computer Prover SN-II combines the accuracy and stability of sonic nozzles with the speed, ease of use and data handling capability of the personal computer. The Computer Prover SN-II is a state of the art meter proving system. At the heart of the Computer Prover SN-II is a standard micro form factor computer. This allows the meter shop the flexibility of sending data to computers at other locations, making permanent copies of the meter test data on disk and using this data to improve meter shop through-put and simplify record keeping.

THE SONIC NOZZLE IS THE STANDARD

The Computer Prover SN-II uses critical/sonic flow technology to provide an accurate and portable measurement standard for gas meter proving. Briefly and simply stated, sonic flow is reached when the differential pressure across the sonic nozzle is high enough to cause the air velocity to reach the speed of sound. Once this minimum differential is reached the volumetric flow rate remains constant and is virtually unaffected by increases in the differential pressure.

FAST AND ACCURATE METER PROVING

The Computer Prover SN-II utilizes Measurement Systems patented internal cycle proving method (#4,996,870). A complete test of a class 250 meter including exercise, leak, open and check tests takes less than one minute. Accuracy is not sacrificed for speed. All of the appropriate proof corrections are made plus the Sonic Nozzles can be calibrated against your own "Master Bell Prover" to insure compatible proof results .

PROVER SETUP BY CHOOSING METER MODEL

The Computer Prover SN-II can be configured with the setup information for all of your meter models. There is no need to turn dials or set switches. The meter model is simply chosen from a menu of meters which are displayed in plain English. Once selected the Prover takes care of the setup, including the sonic nozzles which are chosen auto-matically. Meter model information can be added, deleted or revised at any time.

TANGENT ADJUSTMENT SCREEN

Does meter adjustment put a kink in your production? Let the Computer Prover-SN make the adjustment decisions. Based on the first Open and Check runs the computer determines if the meter is within specifications. If it is out of spec the computer presents the operator with a screen telling him which tangent screws to adjust and num-ber of flats to adjust them (a picture of the tangent can even be brought up by simply pressing a function key). After each succeeding run the Prover goes through this same rou-tine thereby eliminating any guesswork by the operator.

Tangent Adjustment Screen (by pressing a function key)

THE IMPORTANCE OF METER TEST DATA

Of course it is important to determine the accuracy of a meter. But of equal importance is how and where the meter test data is stored and how easily it can be retrieved and manipulated. The Computer Prover-SN stores all critical test data on locally on the computer SSD, or on a networked server. You also have the availability of instant hard copy output using a standard printer.

CUSTOMIZED TO YOUR OPERATION

Another advantage of the Computer Prover-SN is the ability to customize its operation to your meter shop. Since control of the Prover is through software, there are no costly logic boards to replace or modify in order to suit your needs. All changes can be made in software. One example of customizing would be to add software routines which would allow two way communications with a central server.

MODULAR DESIGN - EASY MAINTENANCE

The Computer Prover-SN is also designed with ease of maintenance in mind. This Prover is a totally modular system. There are no hybrid components with their crippling long delivery times. The Computer Prover-SN's modularity takes the anxiety out of maintenance. With one call to Measurement Systems or your local industrial supplier you can have a component replaced off the shelf and delivered without delay.

Magnetic sensor, photo-electric sensor, work table positioning/lifting, touch screen monitor

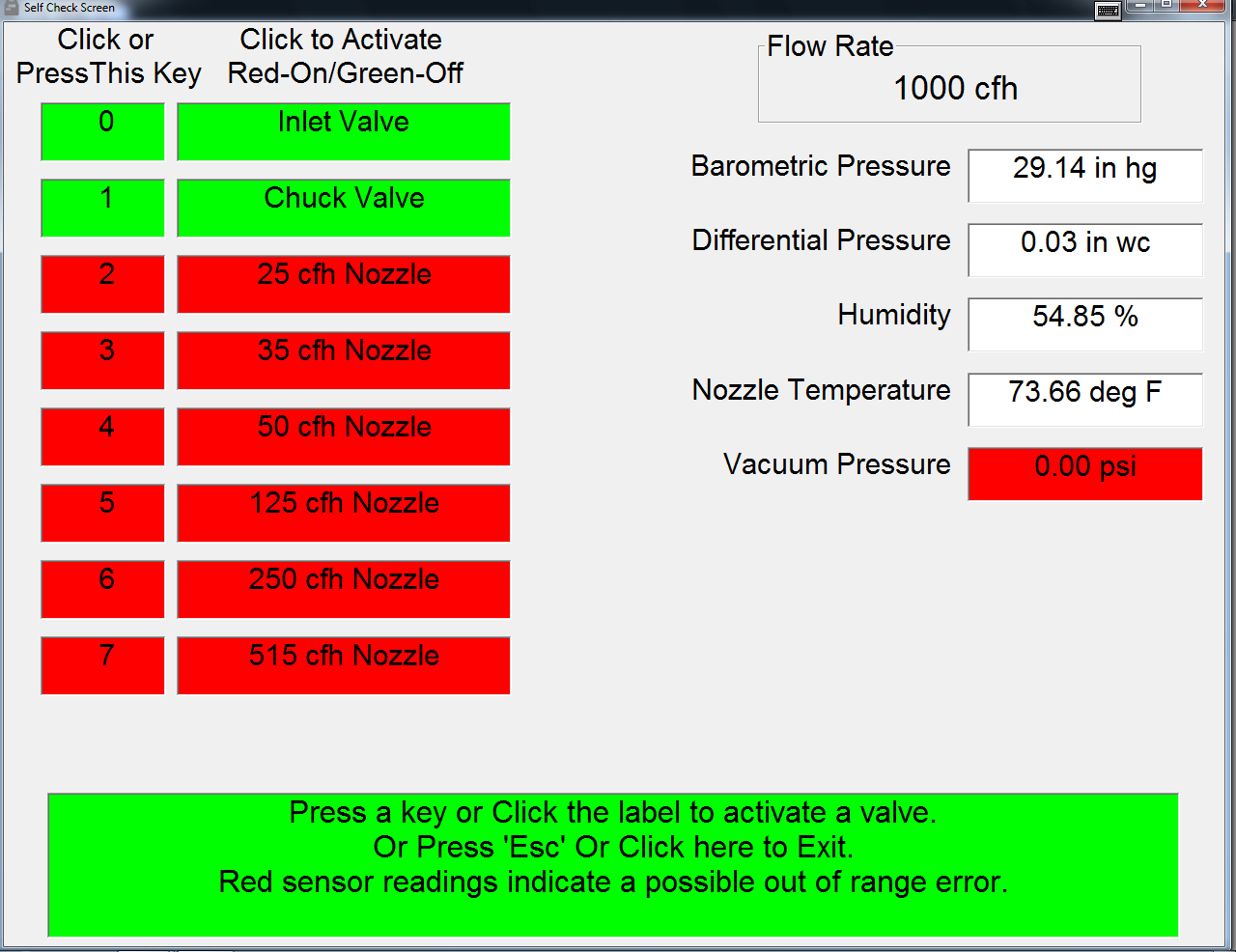

ON BOARD SELF DIAGNOSTICS

The Computer Prover-SN has built in diagnostic routines which are performed each time the Prover is turned on. This allows the operator to verify that the sensors and valves are operating correctly. These tests can be run anytime without turning the Prover off and restarting.

All valves can be operated and sensors monitored in real time allowing simple and straightforward troubleshooting.

REMOTE DIAGNOSTICS

Measurement Systems can also troubleshoot a problem via an internet connection. Once a connection is made, we can work with your operator and see the same display he sees. We can remotely operate the Prover and transfer files or program changes and see the results immediately. The savings on downtime and service calls can be significant.

IF YOU DON'T KNOW COMPUTERS

All this talk about computers may have you asking, "How can I expect my operators to run the Computer Prover-SN?...We're not computer experts". If this is the case, don't be concerned. Using the Prover is easy. Simply turn on the power and the computer screen provides the instructions the operator needs to run the Prover. If you decide to expand the system to take advantage of the Computer Prover-SN'S flexibility Measurement Systems will be there with programming and hardware assistance.

Data entry screen where up to 18 user definable fields are entered and later saved to disk or to a central computer.

The following figure shows an example of a typical screen that the operator would see on the computer monitor after a test run. This screen shows that the Open and Check tests have been run and the Proofs are outside the preset limits. The operator is prompted to do a stroke adjustment on the tangent. (This prover is currently set in the adjust meter mode.). At the bottom of the screen Open test is highlighted as the test to run after the adjustment. The meter can be "JOGGED" (F5) to facilitate adjustment or the meter can be designated as scrap or repair by pressing "F3". Pressing "ENTER" starts another test cycle. This screen is only one of the many screens which are constantly updating the operator with important test status information.

Test screen after a meter test run

STANDARD EQUIPMENT

- Flow rate module capable of 63 flow rates

- Meter temperature sensor

- Differential pressure sensor

- Barometric pressure sensor

- Vacuum sensor

- Humidity sensor

- Patented internal cycle sensor (for high speed proving)

- Castors (for additional mobility)

- Micro PC & touch screen monitor to control the prover with the Windows operating system of your choice.

SPECIFICATIONS

- Meter capacity (maximum): 1000 cfh

- Meter height (maximum): 26.5"

- Meter height (minimum): 11"

- Air required: 1 scfm at 60 psi (min) filtered and regulated

- Vacuum required: 14 scfm (for gas rate nozzles) or 17 scfm (for air rate nozzles) at 3.5 psi vacuum

- Power required: 120 VAC, 60 Hz, 15 Amp, single phase with ground

- Prover dimensions: 58.5" H x 32" W x 32.5" D

- Weight: Approx. 290 lbs

OPTIONAL FEATURES

- Bar code module

- Photo-electric index sensor with visible light beam

- Pulse proving module

- Sonix meter proving module

- Custom Sonic Nozzle flow rates

- Custom Sonic Nozzle proving equipment

- Centralized meter shop data storage system

- Sonic Nozzle Calibration Module